Ceramic Pro ION Two-Component System and What It Means for Your Finish

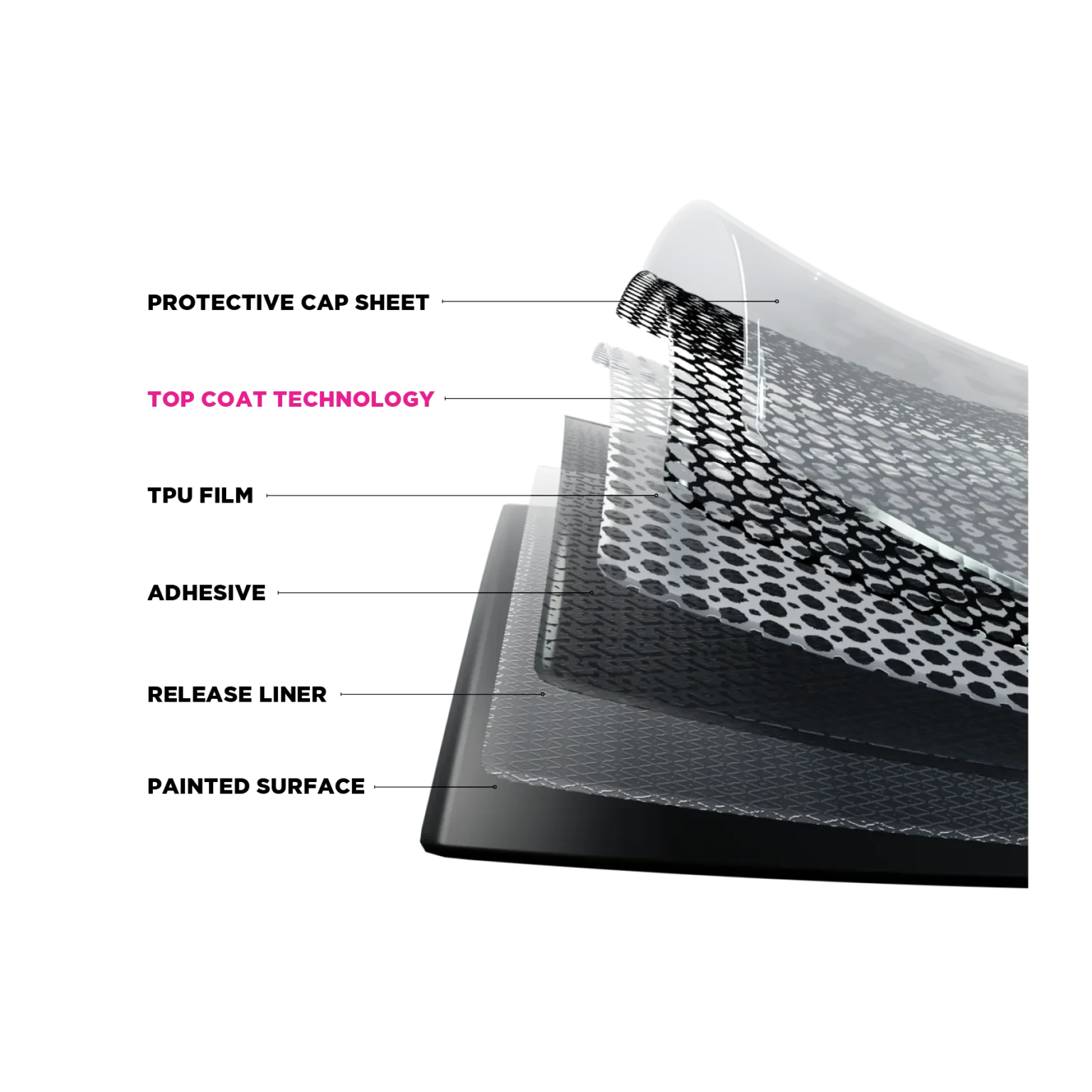

Ceramic Pro ION is installed as a system, which is why prep and process matter as much as the product itself. Ceramic Pro explains that ION Exchange Technology is used to fuse multiple coating layers into a single durable surface. Ceramic Pro ION uses a two-stage approach that includes a base layer and a top layer, which is why the install is planned, not rushed. Ceramic Pro ION is often chosen by owners who want a finish that stays glossy and easier to maintain through changing seasons. Before we apply Ceramic Pro ION, we make sure the paint is clean and ready so the coating can lay down evenly. If you have noticeable swirls or haze, paint correction can be added first so the coated finish looks clearer at pickup. Ceramic Pro ION works best when the surface underneath looks right, because coatings preserve what they sit on.

ION Exchange Coating Prep That Makes the Gloss Look Even

Ceramic Pro ION looks its best when the paint is properly cleaned, decontaminated, and inspected before the coating goes on. We start by checking the paint under lighting so we can see what the surface is doing panel by panel. If the paint needs it, paint correction helps reduce the swirls and fine defects that can distract from reflections. Then we apply Ceramic Pro ION in a controlled process so coverage stays consistent across the hood, doors, and rear panels. Ceramic Pro describes Ceramic Pro ION as a next-generation surface protection approach built around ION Exchange Technology. After installation, we go over care habits so you know how to wash without creating new swirls. Ceramic Pro ION ownership is simple when you follow a clean wash routine and avoid harsh shortcuts. The goal is a finish that looks even up close and stays satisfying to own.